Introduction

Piezoelectric actuators are widely used in various applications such as precision positioning systems, micropumps, valves, and nanopositioning systems. These actuators operate on the principle of piezoelectricity, which is the ability of certain materials to generate displacement in response to applied electrical field. Despite their many advantages, piezoelectric actuators are also known for their reliability issues, which can limit their usefulness in certain applications. This article aims to provide a review of the reliability of piezoelectric actuators. It focuses on the factors that affect their performance and possible solutions to improve their reliability.

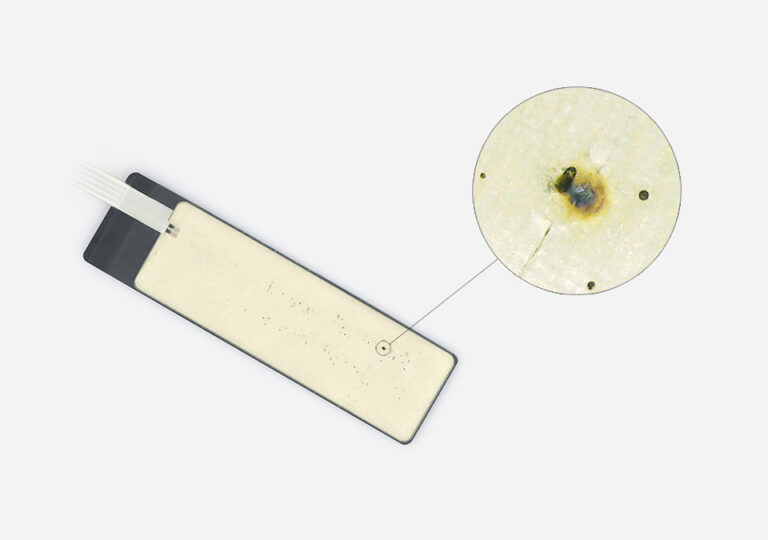

Dielectric breakdown

The reliability of piezoelectric actuators is affected by several factors such as humidity, mechanical stress, and temperature. High levels of humidity can lead to the degradation of piezoelectric materials due to the migration of metal ions in the material. This phenomenon is known as electromigration. It can cause electrical breakdown in the material, leading to a decrease in performance or complete failure of the device. The damage caused by humidity is irreversible, and measures should be taken to prevent exposure to high humidity levels. This can include using protective coatings or packaging materials and ensuring proper storage and handling of the devices.

Cracks

Piezoelectric ceramics are brittle materials that are sensitive to mechanical stress. When subjected to high or cyclic loads, cracks can form and propagate through the material, eventually leading to failure. This is a common problem in piezoelectric devices that are subjected to high levels of vibration or shock. One solution to this crack issue is to use a tougher, more durable material for the piezoelectric element. For example, composite materials that combine piezoelectric ceramics with a tough polymer matrix have been shown to have improved mechanical properties and resistance to cracking. Another approach is to design the device to minimize stress concentrations and distribute the load more evenly across the piezoelectric element. By carefully selecting the shape and size of the piezoelectric component, it is possible to reduce the likelihood of cracking and ensure reliable operation over a longer period. Nevertheless, it is essential to avoid overloading the actuator or subjecting it to excessive vibrations or shocks.

Temperature

Another factor that affects the reliability of piezoelectric actuators is temperature. Temperature cycles can cause the material to expand or contract, resulting in mechanical stress. This can cause cracks and fractures in the actuator. Additionally, temperature changes can also cause changes in the material properties, affecting the actuator’s performance. Our Dragonfly™ and Beetle™ have an operating temperature range from -20 to 65C. Therefore, it is essential to consider this range when applying our products in your systems.

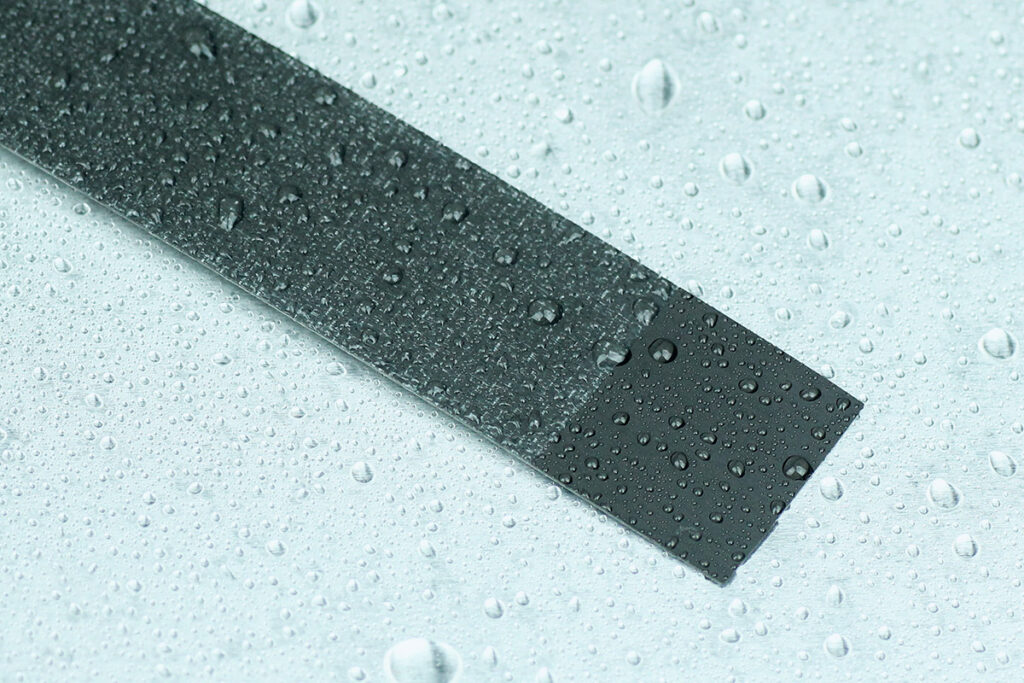

Piezo actuators by Flora

To improve the reliability, we design our products with rigid protective layers to fully encapsulate the piezo layers. This provides superior protection against harsh handling and environments with high humidity and chemical exposure. Moreover, its material is highly optimized to ensure it does not develop cracks even when subjected to extremely high deflection.

The following video demonstrate the durability of our products. They can experience impact, high deflection, and short-term water exposure without any damage.

Conclusion

Piezoelectric actuators are optimal choices for various applications due to their many advantages. However, their reliability can be affected by several factors such as temperature, humidity, and mechanical stress. To improve the reliability of piezoelectric actuators, it is necessary to consider the operating environment, use appropriate materials, and avoid overloading the actuator. Additionally, the use of protective coatings can also improve the actuator’s reliability. By taking these factors into account, it is possible to design and use piezoelectric actuators that are reliable and suitable for a wide range of applications.

One Response

I was excited to uncover this great site. I need to to thank you for your time for this particularly wonderful read!! I definitely enjoyed every part of it and I have you book marked to check out new stuff in your web site.